Back in March, Freeside Atlanta won a LulzBot Mini 3D printer during a hackerspace giveaway they were running. We already have one of their older machines, an AO-100, so we were very familiar with their printers and how easy they were to use. I've used several of LulzBot's printers before - I own an AO-101 myself - and I was really interested to see what the Mini brought to the table.

As I said in my Cube 3D review, I really dislike the idea of "just press go" type of machines. 3D printing is still too young of a technology for mass adoption, and pushing fickle equipment on to the unsuspecting masses will put 3D printing in a negative light.

Having said that: the Mini is probably the best printer I've ever used.

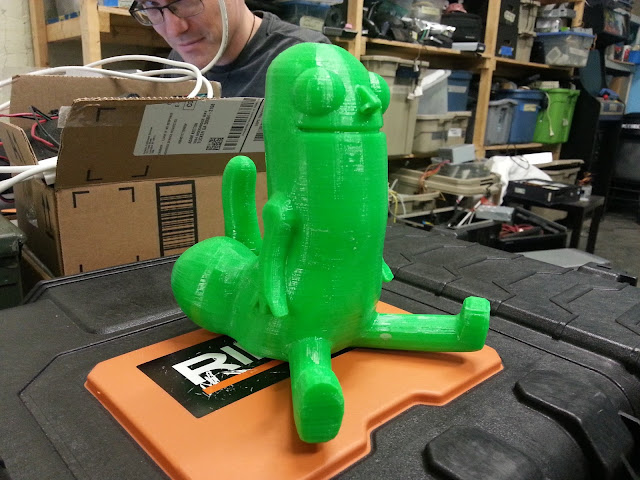

The Mini's name comes from it's generally small build platform of roughly 6" cubed. Normally this would really deter me from using it as I am generally printing large costume pieces, but the small printing volume is the only negative I can possibly say about the machine. The machine comes fully built and ready to use, the frame is attractive and everything is very well constructed. It took us about 20 minutes between unboxing and pulling our first print off of the bed.

Included is a LulzBot branded install of Cura which has all of the settings for the Mini included, so the time between unboxing and printing was incredibly fast. There are several preset quality options, and the highest detail option at 0.1mm produces amazing results. You can go under the hood and tweak all of the print options, but the default settings produce great objects on their own.

But really, the two best features are the PEI printing surface, and the self leveling bed.

PEI is a bit of a new development in the 3D printing world. It is an "aerospace grade glass fabric polyetherimide (PEI) composite" that requires virtually no prep to use in 3D printing. It replaces the usual glass print surface and is adhered directly to the silicone heated bed on the Mini. Unlike printing on borosilicate glass, which you need to apply either kapton tape or ABS juice or purple glue stick to really get large prints to adhere, PEI bonds to both ABS and PLA when heated with no additional work needed.

For example, we 3D printed the entire Xenomorph head - around 38 prints total at ~5 hours each - and didn't have anything come detached from the bed and only very minor lifting on 1 or 2 very long prints.

Once the surface cools, your prints will come loose with very little effort, and only large flat objects need to be pried off using a clam knife. Occasionally I will clean the surface with denatured alcohol to get rid of any dust or skin oils left over from the bed being touched while removing objects, but that's the most maintenance I've had to do.

However, after about 500 printing hours being put on it, the surface has started to bubble and should probably be replaced soon. I am chalking that up to having 20 or so people at the space using it, and not everyone treating it as delicately as they should. If you are using it yourself and you treat the machine with respect - and especially waiting for the bed to fully cool down so the PEI releases it's grip - I doubt you'd have the bubbling problem.

The self leveling bed is fantastic, and virtually negates the need for any maintenance and upkeep. Unlike printers like the PrintrBot Play which use a magnetic sensor, the Mini uses electrical signal sent through the print head. In the corners of the printer are 4 metal discs, and the machine uses the change in voltage to measure when the nozzle has made contact.

On my printers at home, keeping the bed in level is the biggest struggle and the cause for any real printing issues I have. When I am building a space gun or some sci-fi armor and I'm planning on putting 200+ hours on the machines for just a single project, reducing the down time between jobs is a life saver. Using the Mini, I know that the bed will always be perfectly level and my props will come out pixel accurate to the 3D models.

The Mini comes with a 0.5mm nozzle, which compared to the 0.35mm nozzle I use at home, I was worried that the print quality would suffer. But between the PEI bed and the self leveling feature, and the rock solid construction of the body and mechanical elements, the actual print quality print for print is some of the best I've seen off of an FDM printer.

I'm debating on whether or not I want to buy one for myself, but I am strongly leaning towards doing so. My only reservation would be to wait until the stand out features of the Mini make their way into the TAZ line of printers from LulzBot, which I'm sure is inevitable. Having a 300 mm x 300 mm printing surface on PEI with a self leveling bed would make them the only FDM printer I'd ever want to use again.

If you want a printer that is reliable and doesn't require frequent upkeep, then I can't recommend this printer enough.

As I said in my Cube 3D review, I really dislike the idea of "just press go" type of machines. 3D printing is still too young of a technology for mass adoption, and pushing fickle equipment on to the unsuspecting masses will put 3D printing in a negative light.

Having said that: the Mini is probably the best printer I've ever used.

The Mini's name comes from it's generally small build platform of roughly 6" cubed. Normally this would really deter me from using it as I am generally printing large costume pieces, but the small printing volume is the only negative I can possibly say about the machine. The machine comes fully built and ready to use, the frame is attractive and everything is very well constructed. It took us about 20 minutes between unboxing and pulling our first print off of the bed.

Included is a LulzBot branded install of Cura which has all of the settings for the Mini included, so the time between unboxing and printing was incredibly fast. There are several preset quality options, and the highest detail option at 0.1mm produces amazing results. You can go under the hood and tweak all of the print options, but the default settings produce great objects on their own.

But really, the two best features are the PEI printing surface, and the self leveling bed.

PEI is a bit of a new development in the 3D printing world. It is an "aerospace grade glass fabric polyetherimide (PEI) composite" that requires virtually no prep to use in 3D printing. It replaces the usual glass print surface and is adhered directly to the silicone heated bed on the Mini. Unlike printing on borosilicate glass, which you need to apply either kapton tape or ABS juice or purple glue stick to really get large prints to adhere, PEI bonds to both ABS and PLA when heated with no additional work needed.

For example, we 3D printed the entire Xenomorph head - around 38 prints total at ~5 hours each - and didn't have anything come detached from the bed and only very minor lifting on 1 or 2 very long prints.

Once the surface cools, your prints will come loose with very little effort, and only large flat objects need to be pried off using a clam knife. Occasionally I will clean the surface with denatured alcohol to get rid of any dust or skin oils left over from the bed being touched while removing objects, but that's the most maintenance I've had to do.

However, after about 500 printing hours being put on it, the surface has started to bubble and should probably be replaced soon. I am chalking that up to having 20 or so people at the space using it, and not everyone treating it as delicately as they should. If you are using it yourself and you treat the machine with respect - and especially waiting for the bed to fully cool down so the PEI releases it's grip - I doubt you'd have the bubbling problem.

The self leveling bed is fantastic, and virtually negates the need for any maintenance and upkeep. Unlike printers like the PrintrBot Play which use a magnetic sensor, the Mini uses electrical signal sent through the print head. In the corners of the printer are 4 metal discs, and the machine uses the change in voltage to measure when the nozzle has made contact.

On my printers at home, keeping the bed in level is the biggest struggle and the cause for any real printing issues I have. When I am building a space gun or some sci-fi armor and I'm planning on putting 200+ hours on the machines for just a single project, reducing the down time between jobs is a life saver. Using the Mini, I know that the bed will always be perfectly level and my props will come out pixel accurate to the 3D models.

The Mini comes with a 0.5mm nozzle, which compared to the 0.35mm nozzle I use at home, I was worried that the print quality would suffer. But between the PEI bed and the self leveling feature, and the rock solid construction of the body and mechanical elements, the actual print quality print for print is some of the best I've seen off of an FDM printer.

I'm debating on whether or not I want to buy one for myself, but I am strongly leaning towards doing so. My only reservation would be to wait until the stand out features of the Mini make their way into the TAZ line of printers from LulzBot, which I'm sure is inevitable. Having a 300 mm x 300 mm printing surface on PEI with a self leveling bed would make them the only FDM printer I'd ever want to use again.

If you want a printer that is reliable and doesn't require frequent upkeep, then I can't recommend this printer enough.